Date:2020-06-10 14:44

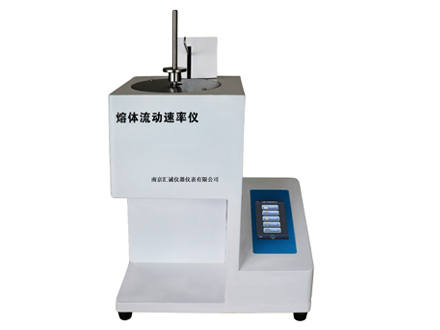

Instrument introduction

This machine is not only suitable for engineering plastics such as polyethylene, polysulfone, fluoroplastics and nylon with high melting temperature, but also for plastics with low melting temperature such as polyethylene, polystyrene, polypropylene ABS resin and polyformaldehyde resin. It is especially suitable for colleges and universities, scientific research institutions, quality inspection institutions, plastic production enterprises, plastic products and petrochemical industry.

The whole machine adopts advanced arm control system, temperature control mode adopts PID adjustment mode, equipped with 5-inch high-definition touch screen, with rich display information and stable and reliable performance. The heating sleeve is an integrated structure, with low failure rate, high heating power, fast heating speed and high constant temperature accuracy. The tester is compact and beautiful in structure, and has the function of upper temperature protection.

Technical parameters:

1. Display mode: 5-inch color touch screen

2.Measurement methods: MFR, MVR and density.

3. Control system: arm control system, temperature control mode adopts PID regulation mode

4. Flow rate measurement range:

|

Product model |

Flow rate measurement range |

|

RNG-A1 |

(0.1~100g)/10min

|

|

RNG-B1 |

(0.1~100g)/10min或(0.01~200cm³)/10min |

5. Cutting mode: automatic sample cutting (time control, displacement control), manual button automatic sample cutting

6. Automatic cutting setting: sample cutting interval: 0.1 ~ 10000.0s, any setting;

Setting length of cutting material: 0.1-30mm, any setting;

7. Temperature control range: room temperature~450℃

8. control accuracy:≤±0.2℃

9. Temperature display resolution:0.1℃

10. Temperature recovery time:<4min

11. Sample adding method: manual loading

12. Displacement measurement and control:

a) Structure: 2000 line encoder to ensure accurate and true displacement data;

b) measuring range:0-30mm

c) Displacement resolution:0.001mm

d) measurement accuracy:0.1mm

13. time-out parameter:

a) Timing time range:0.1~10000.0s;

b) Timing resolution:0.01s

14. Feed part:

a) Outlet - diameter: Φ 2.095 ± 0.0005mm; length: 8 ± 0.025mm

b) Charging barrel - diameter: Φ 9.550 ± 0.025mm; length: 152 ± 0.1mm

c) Piston rod head - diameter: Φ 9.475 ± 0.015mm; length: 6.350 ± 0.1mm

15. Instrument size: length 460mm × width 300mm × height 650mm

16. Instrument weight:15Kg

17. Power Supply:220V、50HZ、800W

18. Standard test load: (relative error of test load ≤ 0.5%)

a) Standard configuration level 8:0.325kg、1.200kg、2.160kg、3.800kg、5.000kg、10.000kg、12.500kg、21.600kg

b) Optional level 3:1kg 、1.05kg、31.6kg

19. Optional: connect computer and micro printer to realize data calculation, storage, printing and other functions

Reference standards:

GB/T3682-2000、ASTMD1238、BS2782、ISO1133:MFR in 2005。

Instrument configuration:

1. One host

2. One die (Φ 2.095mm)

3. One blanking drill for die

4. One wiping rod

5. One tapping die rod

6. One leveling level

7. One charging hopper

8. One test material tray

9. One power cord

10.A set of weights

a) 1Weight:325g 1 weight

b) 2weight:875 g 1 weight

c) 3weight:1835g 1 weight

d) 4weight:2500g 1 weight

e) 5weight:2915g 1 weight

f) 6weight:3475g 1 weight

g) 7weight:4675 g 1 weight

h) 8weight:5000 g 1 weight

i) 9weight:675 g 1 weight(Optional)

j) 10weight:725 g 1 weight(Optional)

k) 11weight:10kg砝 1 weight(Optional)